USA +1(888).396.4128

USA +1(888).396.4128 +61(07) 3161-6600

+61(07) 3161-6600-

+01(993) 353-5895 al 97

+01(993) 353-5895 al 97 - MEXICO AFFLIATE www.ram100.com.mx

USA +1(888).396.4128

USA +1(888).396.4128 +61(07) 3161-6600

+61(07) 3161-6600 +01(993) 353-5895 al 97

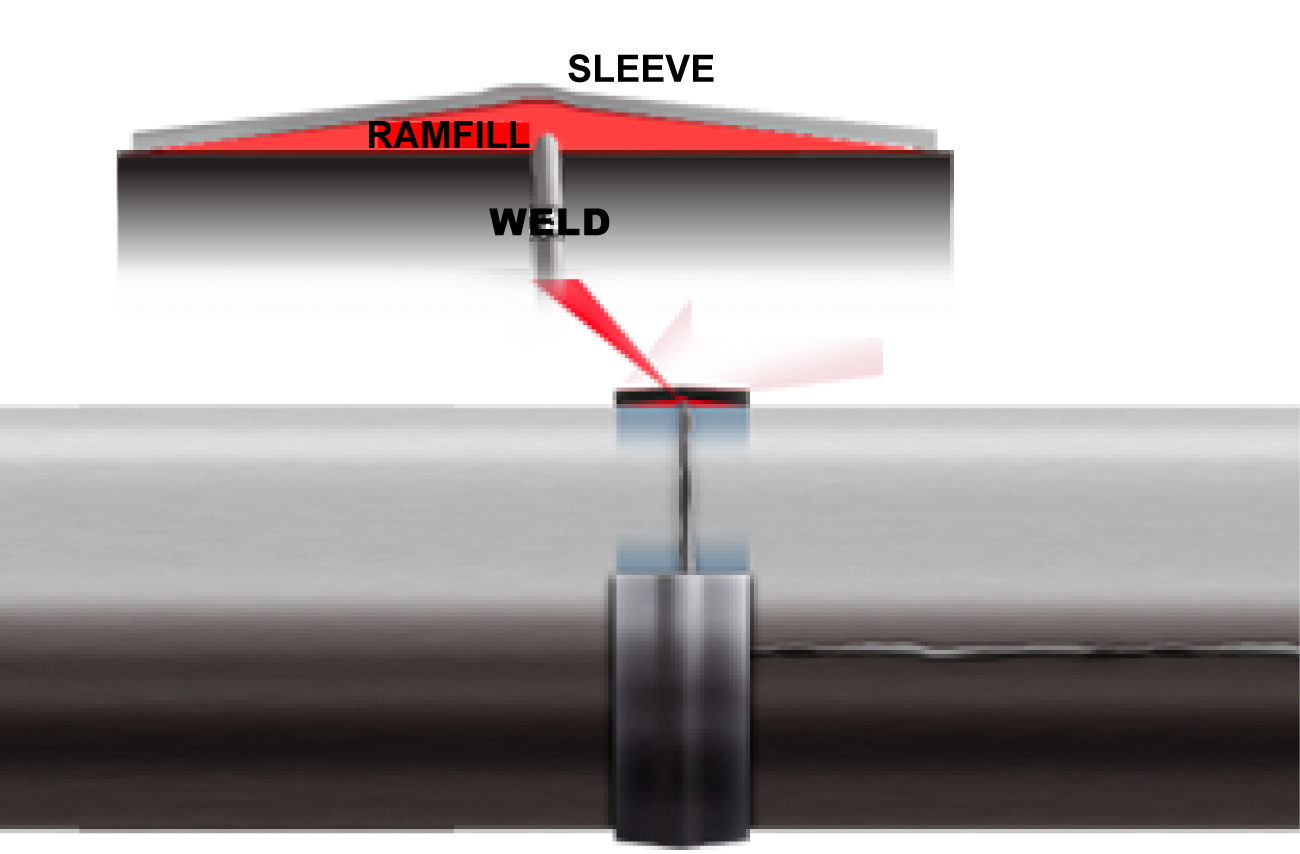

+01(993) 353-5895 al 97RAMFILL-RS is a boiler-type repair sleeve for reinforcement of weld deficiencies. Its pyramidal design and a convex bent in the center to properly fit the existing weld to be repaired is a Patented Product in Mexico (Patent # MX/a/2011/005026). Its geometric shape improves the mechanical stress resistance of the sleeve. It is manufactured without welds, with specifications, diameter, and thickness, as requested by each project.

Each halve of the RAMFILL-RS sleeve is manufactured with two bevel sections along the longitudinal ends, to prevent welding product to reach the pipeline when the longitudinal welding is performed on the sleeve as well as to maintain the annular space free of welding gases. RAMFILL-RS repair sleeves are a patented RAM-100® product that was developed in response to the demand for a fast, safe, and permanent solution to repair weld deficiencies such as:

RAMFILL-RS steel sleeves are repair systems for girth welds of hydrocarbon transmission pipelines. Each repair system is composed by two steel halves welded to each other and manufactured under the following international standards:

Click the image to the left for an overview presentation of our Steel Reinforcement Sleeves in English for an overview presentation of our company in Spanish, click the following link: RAM-100 del Sureste

Click the image below for an overview presentation of our Steel Reinforcement Sleeves in English for an overview presentation of our company in Spanish, click the following link: RAM-100 del Sureste