USA +1(888).396.4128

USA +1(888).396.4128 +61(07) 3161-6600

+61(07) 3161-6600-

+01(993) 353-5895 al 97

+01(993) 353-5895 al 97 - MEXICO AFFLIATE www.ram100.com.mx

USA +1(888).396.4128

USA +1(888).396.4128 +61(07) 3161-6600

+61(07) 3161-6600 +01(993) 353-5895 al 97

+01(993) 353-5895 al 97

RAMFILL-MC repair systems are manufactured under the international standards ANSI/ASME B31.4 and B31.8 from carbon-steel plates or carbon-steel pipes, in any specification, diameter and thickness, and according to the client’s request or project requirements.

RAM-100 complies with the following International Standards for the manufacture of RAMFILL-MC steel reinforcement sleeve repair systems:

RAMFILL-MC sleeves are easy and fast to install, and because of our manufacturing processes comply with tolerances and guidelines outlined in API/ANSI/ASME standards, RAMFILL-MC sleeves can be installed in operating pipelines.

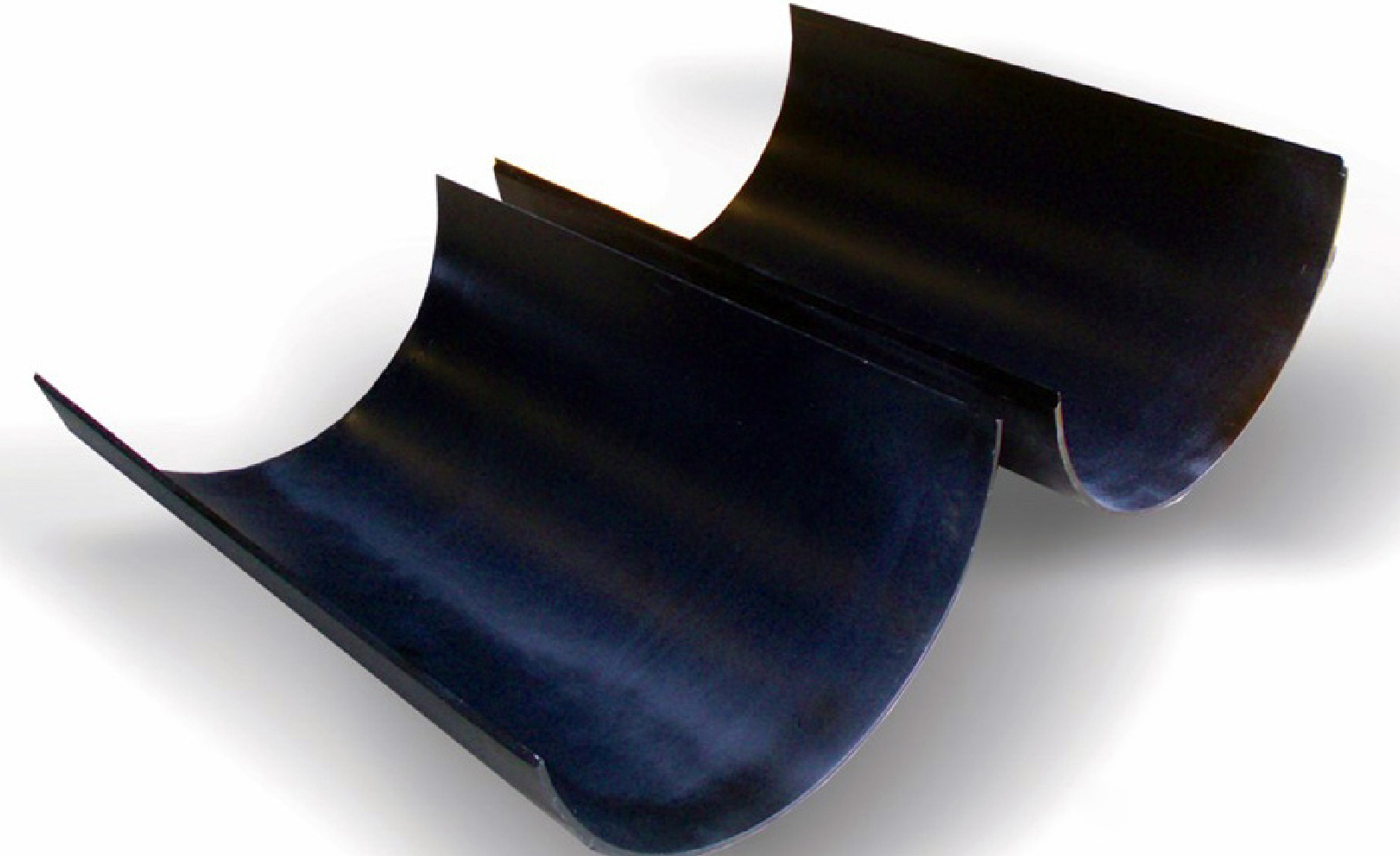

Our full encirclement sleeves type 'A' are installed only with longitudinal welds between each halve, without welding to the pipeline. This type of repair is accepted for pipelines with integrity deficiencies such as:

RAMFILL-MC repair systems can be installed in pipelines that must be reinforced for safety such as those pipeline systems located in High Consequence Areas.

Our RAMFILL-MC repair systems, are full encirclement sleeves which require welding to the pipeline because of the deficiencies found during an integrity inspection. These repair systems are installed with longitudinal weld joining both halves, and an axial weld to the pipeline on each of the sleeve. This type of repair system is accepted for repairing pipelines with integrity deficiencies, such as:

RAMFILL-MC repair systems can be converted to a Type ‘B’ repair system when welded to a pipe through a qualified welding procedure with certified welders. When this is required, a radiographic or ultrasonic inspection must be performed to the axial and longitudinal welds. After performing a mechanical integrity analysis of the deficiency identified during the inspection, and according to the applied assessment method, in order to reinforce the pipeline, a pipeline repair alternative must be selected using as primary criteria, the recovery of mechanical resistance suffered by loss of material, and up to reaching the rupture strength of the original conditions of the pipe. The repair and analysis urgency depend on the severity of the flaw, its location, depth, length, direction, strategic value of the pipeline and threat to the environment and population, as well as the potential consequences of the deficiency.

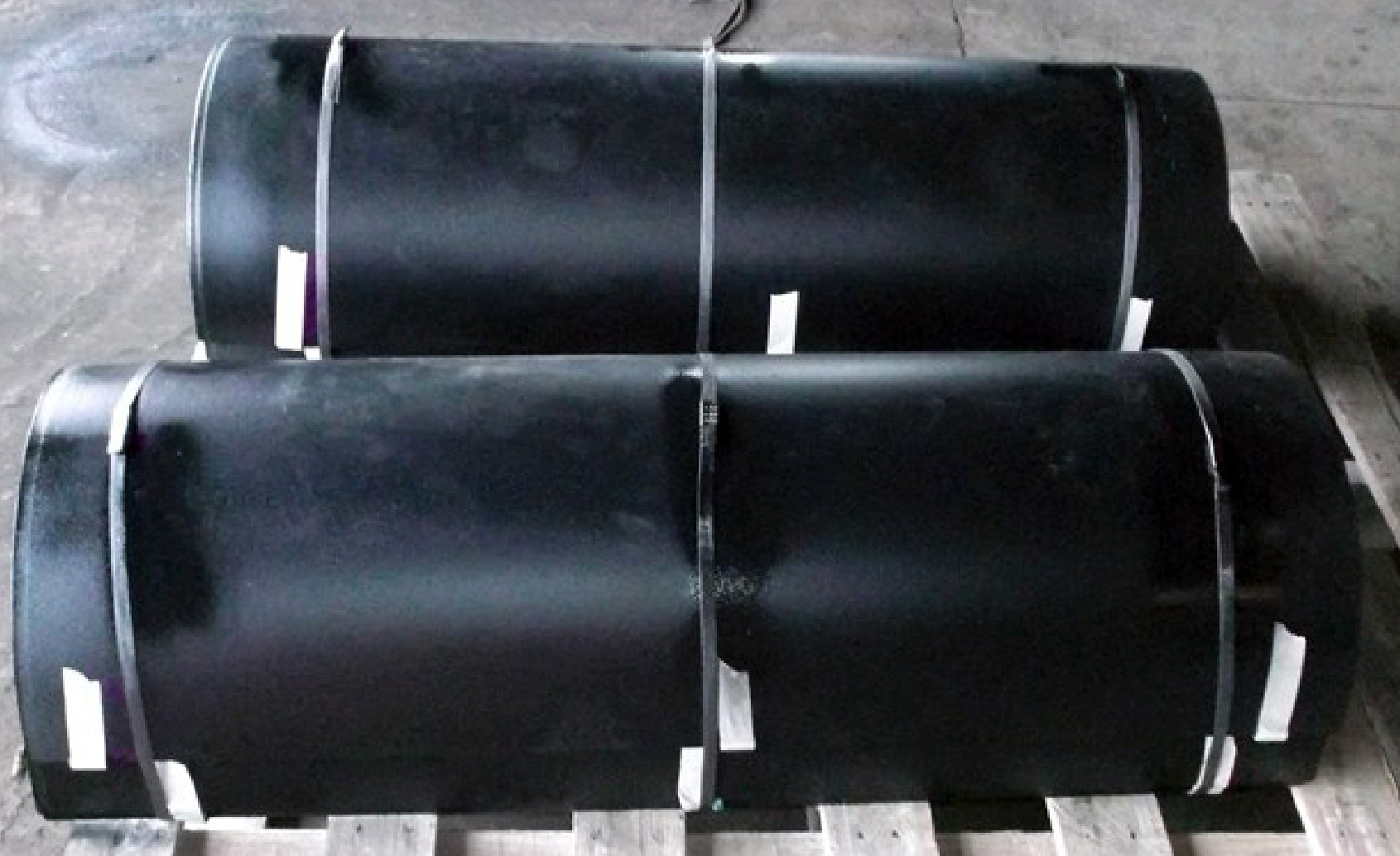

The most common size of RAMFILL-MC sleeves is of 1.0 m in length in all API diameters, from ASMI plate with the same or superior elasticity of the pipeline to be reinforced. If needed, it can be manufactured up to 3.0 m in length.

RAMFILL-MC repair systems are easily installed as each is manufactured to fit perfectly to the pipeline being repaired. Each halve is delivered with a beveled section on the longitudinal ends to rest evenly on the pipeline leaving an adequate space for the welding deposit. These beveled sections also prevent dripping and possible contamination of the welding when mixed with RAM-100 epoxy resin when applied as anti-corrosive mechanical protection in the residual gap.

Click the image to the left for an overview presentation of our Steel Reinforcement Sleeves in English for an overview presentation of our company in Spanish, click the following link: RAM-100 del Sureste